From S.H.O.

S.H.O. Drive Mark I will be the world's first S.H.O. drive. Come back in the next couple months for major updates! S.H.O. talk 21:35, 5 May 2016 (PDT)

S.H.O. Drive Mark Alpha refers to the original plan for world's first S.H.O. Drive. The actual build will incorporate clear acrylic tubes to elevate the wooden panels inside the crate for maximum transparency and minimization of the ways to hide batteries. A build and demonstration was planned for the 4th of July, but I decided that more planning was need in terms of the logistics of the demonstration as well as the final shape of the S.H.O. Coils. The build time to make the S.H.O. Drive is, and I estimate, to be around 5 hours. Since the video showing the build must be done in one take, I have to make sure that I have my ideas lined up, so this way they come out smoothly in the presentation.

Also, cost information is not listed for S.H.O. Drive Alpha because it is preliminary work, but when the world's first S.H.O. drive is built, the cost information for that build will be made available. Sincerely, S.H.O. talk 20:06, 4 July 2016 (PDT)

Presentation Outline (for S.H.O. Drive Alpha)

Presentation

Build Gallery

August 14, 2016

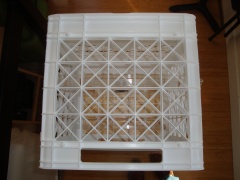

| S.H.O. Drive Crate

Rear View |

| S.H.O. Drive Crate

Rear View (Leveled) |

| S.H.O. Drive Crate

Rear View (with flash) |

| S.H.O. Drive Crate

Interior View |

| S.H.O. Drive Crate

Interior View (Center) |

| S.H.O. Drive Crate

Interior View from Rear (revealing left-side wall) |

| S.H.O. Drive Crate

Interior View from Rear (revealing right-side wall) |

| S.H.O. Drive Crate

Diagonal View (Top Left Rear) |

| S.H.O. Drive Crate

Front View |

| S.H.O. Drive Crate

Diagonal View (Top Front) |

| S.H.O. Drive Crate

Diagonal View (Top Left Front) |

| S.H.O. Drive Crate

Diagonal View (Top Right Rear) |

| S.H.O. Drive Crate

Diagonal View (Top Rear) |

| S.H.O. Drive Crate

Top View |

| S.H.O. Drive Build Room

on August 14, 2016 (with North Wall) |

| S.H.O. Drive Build Room

on August 14, 2016 (with South Wall) |

|

Dimensions

Distance along shaft length (Depth)

For design plan as of August 14, 2016

inches

1 7/8 back end assembly behind panel

5/8 square acrylic support rod

1/4 square acrylic support rod

1/2 acrylic panel

7/8 vinyl cup hooks

3/8 air gap

1 1/2 neo magnets

3/8 air gap

7/8 vinyl cup hooks

1/2 acrylic panel

1/4 square acrylic support rod

5/8 square acrylic support rod

3 3/8 front end assembly in front of panel

12 total length of shaft

For design plan as of August 28, 2016

inches

1 7/8 back end assembly behind panel

5/8 square acrylic support rod

1/2 acrylic panel

1 1/4 vinyl cup hooks

1/4 air gap

1 1/2 neo magnets

1/4 air gap

1 1/4 vinyl cup hooks

1/2 acrylic panel

5/8 square acrylic support rod

3 3/8 front end assembly in front of panel

12 total length of shaft

Reason for change: The wound coils have a larger thickness to due an intentionally-reduced perimeter of the actual winding vs. the original plan.

April 2016 Presentation

(Top)

| I

|

Introduction

Summary of measuring devices, back up and safety equipment, and camcorder (+accessories)

|

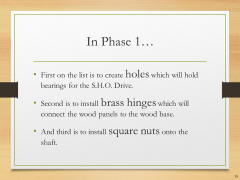

| 1

|

Phase 1

Holes, brass hinges, square nuts

|

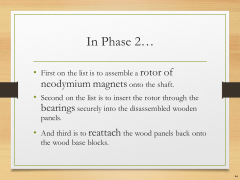

| 2

|

Phase 2

Neodymium magnets and bearings

|

| 3

|

Phase 3

Spool, coils, and ceiling hooks

|

| 4

|

Phase 4

No hidden batteries, increase rigidity, hex nuts, terminal rings, toggle switch, fan blades, and extended test run

|

| 5

|

Phase 5

Heavy duty basket, S.H.O. Drive insertion, secure meters, and portable extended test run

|

| 6

|

Phase 6

Square tote, plastic spools, protective edge trim, and enclosed extended test run

|

| 7

|

Phase 7

Prepare elevated test platform, outdoor test setup, camcorder hookup to portable power, and outdoor extended test run

|

Site map

HQ ● Glossary ● April 2016 Presentation