|

|

| Line 32: |

Line 32: |

| | |lines=10 | | |lines=10 |

| | |footer= | | |footer= |

| − | |Let's Build the S.H.O. Drive! - Slide 018 of 176.png||'''In Phase 1…<br>• First on the list is to create holes which will hold bearings for the S.H.O. Drive.<br>• Second is to install brass hinges which will connect the wood panels to the wood base.<br>• And third is to install square nuts onto the shaft. | + | |Let's Build the S.H.O. Drive! - Slide 018 of 176.png||'''In Phase 1…'''<br>• First on the list is to create holes which will hold bearings for the S.H.O. Drive.<br>• Second is to install brass hinges which will connect the wood panels to the wood base.<br>• And third is to install square nuts onto the shaft. |

| | |Let's Build the S.H.O. Drive! - Slide 019 of 176.png||'''2 Barn Birdhouse Kits'''<br>''(Phase 1 Parts)''<br>• The wood panels I will be using will come from 2 SawDust Bros. Birdhouse Kits which I obtained from Woodcraft.<br>• Why birdhouse kits? Well each birdhouse kit is packed with many pieces of wood of various sizes, which I may use in the future. | | |Let's Build the S.H.O. Drive! - Slide 019 of 176.png||'''2 Barn Birdhouse Kits'''<br>''(Phase 1 Parts)''<br>• The wood panels I will be using will come from 2 SawDust Bros. Birdhouse Kits which I obtained from Woodcraft.<br>• Why birdhouse kits? Well each birdhouse kit is packed with many pieces of wood of various sizes, which I may use in the future. |

| | |Let's Build the S.H.O. Drive! - Slide 020 of 176.png||'''Saving Time'''<br>''(Protocols)''<br>• But the main reason why I purchased two Birdhouse kits was for the two front panels, which have holes that are nearly the right size for the project.<br>• I will use the front panels from each kit as support structures to carry the weight of the bearings, rotor, and conductive copper coils. | | |Let's Build the S.H.O. Drive! - Slide 020 of 176.png||'''Saving Time'''<br>''(Protocols)''<br>• But the main reason why I purchased two Birdhouse kits was for the two front panels, which have holes that are nearly the right size for the project.<br>• I will use the front panels from each kit as support structures to carry the weight of the bearings, rotor, and conductive copper coils. |

| Line 41: |

Line 41: |

| | |Let's Build the S.H.O. Drive! - Slide 025 of 176.png||'''Dremel Accessory Set'''<br>''(Phase 1 Tools)''<br>• In order to finish the holes nicely to size, I will attach items from the Dremel 687-01 General Purpose Accessory Set I purchased at Fry’s Electronics. | | |Let's Build the S.H.O. Drive! - Slide 025 of 176.png||'''Dremel Accessory Set'''<br>''(Phase 1 Tools)''<br>• In order to finish the holes nicely to size, I will attach items from the Dremel 687-01 General Purpose Accessory Set I purchased at Fry’s Electronics. |

| | |Let's Build the S.H.O. Drive! - Slide 026 of 176.png||'''Sanding Bands & Drum'''<br>''(Phase 1 Tools)''<br>• The Dremel tools from the kit that I will use are the 432 Sanding Bands and the 407 Sanding Drum.<br>• The sanding area will be ½” (or about 13 mm) thick, which will be perfect for sanding into the ½” (or about 13 mm) thick wood panels which will hold the bearings. | | |Let's Build the S.H.O. Drive! - Slide 026 of 176.png||'''Sanding Bands & Drum'''<br>''(Phase 1 Tools)''<br>• The Dremel tools from the kit that I will use are the 432 Sanding Bands and the 407 Sanding Drum.<br>• The sanding area will be ½” (or about 13 mm) thick, which will be perfect for sanding into the ½” (or about 13 mm) thick wood panels which will hold the bearings. |

| − | |Let's Build the S.H.O. Drive! - Slide 027 of 176.png||'''Plywood Surface'''<br>''(Equipment)''<br>• To make better use of the workbench for the rest of the project, I will cover the top with two pieces of Baltic Birch plywood from Woodcraft:<br>• The side lengths are 12” (or about 30 cm)''<br>• The thickness of each is 1/2” (or about 13 mm) | + | |Let's Build the S.H.O. Drive! - Slide 027 of 176.png||'''Plywood Surface'''<br>''(Equipment)''<br>• To make better use of the workbench for the rest of the project, I will cover the top with two pieces of Baltic Birch plywood from Woodcraft:<br>• The side lengths are 12” (or about 30 cm)<br>• The thickness of each is 1/2” (or about 13 mm) |

| | |Let's Build the S.H.O. Drive! - Slide 028 of 176.png||'''C-Clamps'''<br>''(Equipment)''<br>• To hold the plywood to the workbench, I will use 3 in. Industrial C-Clamps that I obtained from a Harbor Freight Tools store. | | |Let's Build the S.H.O. Drive! - Slide 028 of 176.png||'''C-Clamps'''<br>''(Equipment)''<br>• To hold the plywood to the workbench, I will use 3 in. Industrial C-Clamps that I obtained from a Harbor Freight Tools store. |

| | |Let's Build the S.H.O. Drive! - Slide 029 of 176.png||'''Ash Wood Blocks'''<br>''(Phase 1 Parts)''<br>• I also have two separate Ash wood blocks, also from Woodcraft that are about 2 inches by 2 inches thick. That’s about 50 millimeters on each side. Their length is about 8 inches long, or about 200 millimeters. These blocks will serve as the “feet” of the S.H.O. Drive.<br>• If you’re wondering what Ash wood is used for, it’s a wood often used in baseball bats. | | |Let's Build the S.H.O. Drive! - Slide 029 of 176.png||'''Ash Wood Blocks'''<br>''(Phase 1 Parts)''<br>• I also have two separate Ash wood blocks, also from Woodcraft that are about 2 inches by 2 inches thick. That’s about 50 millimeters on each side. Their length is about 8 inches long, or about 200 millimeters. These blocks will serve as the “feet” of the S.H.O. Drive.<br>• If you’re wondering what Ash wood is used for, it’s a wood often used in baseball bats. |

| Line 66: |

Line 66: |

| | |lines=10 | | |lines=10 |

| | |footer= | | |footer= |

| | + | |Let's Build the S.H.O. Drive! - Slide 018 of 176.png||'''In Phase 2…'''<br>• First on the list is to assemble a rotor of neodymium magnets onto the shaft.<br>• Second on the list is to insert the rotor through the bearings securely into the disassembled wooden panels.<br>• And third is to reattach the wood panels back onto the wood base blocks. |

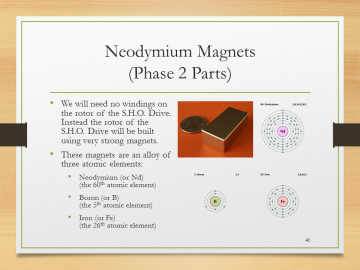

| | + | |Let's Build the S.H.O. Drive! - Slide 045 of 176.png||'''Neodymium Magnets'''<br>''(Phase 2 Parts)''<br>• We will need no windings on the rotor of the S.H.O. Drive. Instead the rotor of the S.H.O. Drive will be built using very strong magnets.<br>• These magnets are an alloy of three atomic elements:<br>• Neodymium (or Nd)'''<br>''(the 60th atomic element)''<br>• Boron (or B)'''<br>''(the 5th atomic element)''<br>• Iron (or Fe)'''<br>''(the 26th atomic element) |

| | + | |Let's Build the S.H.O. Drive! - Slide 046 of 176.png||'''Neodymium Magnets'''<br>''(Phase 2 Parts)''<br>• These Neodymium magnets are from Magnet4less.com and are pound-for-pound some of the strongest permanent magnets that you yourself can buy on the market today.<br>• These are often used in making wind turbine generators. |

| | + | |Let's Build the S.H.O. Drive! - Slide 047 of 176.png||'''Neodymium Magnets'''<br>''(Phase 2 Parts)''<br>• Because these permanent magnets possess a stronger magnetic field, they will exert stronger magnetic forces on currents in S.H.O. coil.<br>• In turn, the current in the wires will be able to exert stronger magnetic forces on these permanent magnets. |

| | + | |Let's Build the S.H.O. Drive! - Slide 048 of 176.png||'''Securing the Shaft'''<br>''(Protocols)''<br>• To secure the shaft into place, I will thread some extra square nuts temporarily onto the shaft and clamp them down onto the Black & Decker Workmate with the Bessey XM7 3-Inch Metal Spring Clamp that I obtained from inside a Woodcraft store. |

| | + | |Let's Build the S.H.O. Drive! - Slide 049 of 176.png||'''Magnetic Pole Detector'''<br>''(Measuring Equipment)''<br>• Before I attempt to attach the magnets to the rotor, I will identify the north pole of each magnet with a Magnetic Pole Detector that I purchased from Magnet4Less.com |

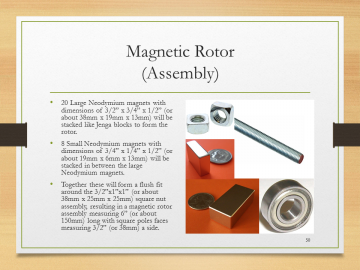

| | + | |Let's Build the S.H.O. Drive! - Slide 050 of 176.png||'''Magnetic Rotor'''<br>''(Assembly)''<br>• 20 Large Neodymium magnets with dimensions of 3/2” x 3/4” x 1/2” (or about 38mm x 19mm x 13mm) will be stacked like Jenga blocks to form the rotor.<br>• 8 Small Neodymium magnets with dimensions of 3/4” x 1/4” x 1/2” (or about 19mm x 6mm x 13mm) will be stacked in between the large Neodymium magnets.<br>• Together these will form a flush fit around the 3/2”x1”x1” (or about 38mm x 25mm x 25mm) square nut assembly, resulting in a magnetic rotor assembly measuring 6” (or about 150mm) long with square poles faces measuring 3/2” (or 38mm) a side. |

| | + | |Let's Build the S.H.O. Drive! - Slide 051 of 176.png||'''Wood Panels'''<br>''(Disassembly)''<br>• I will unscrew the hinges off of the wood panels, enabling insertion of the shaft and bearings into the panel holes. |

| | + | |Let's Build the S.H.O. Drive! - Slide 052 of 176.png||'''Bearings'''<br>''(Phase 2 Parts)''<br>• I ordered shielded ball bearings from VXB at Amazon.com. These bearings are rated as having electric motor quality and will carry the weight of the shaft. <br>• These bearings should fit snuggly into the holes carved into the wood panels. |

| | + | |Let's Build the S.H.O. Drive! - Slide 053 of 176.png||'''Inserting the Rotor'''<br>''(Assembly)''<br>• After that, I will insert the rotor assembly, through the installed bearings.<br>• Then I will fasten the wood panels back onto to the base blocks. |

| | }} | | }} |

| | <div style="clear:both"></div> | | <div style="clear:both"></div> |

| Line 74: |

Line 84: |

| | |lines=10 | | |lines=10 |

| | |footer= | | |footer= |

| | + | |Let's Build the S.H.O. Drive! - Slide 054 of 176.png||'''In Phase 3…'''<br>• First on the list is to make a custom rectangular spool for winding copper wire.<br>• Second is to make the two S.H.O. coils by winding copper wire around the rectangular spool, and then carefully (and separately) bending each of these coils into the shape of an S.<br>• And third is to install each completed S.H.O. coil onto the ceiling hooks to be installed on the wood panels. |

| | + | |Let's Build the S.H.O. Drive! - Slide 055 of 176.png||'''Magnet Wires'''<br>''(Phase 3 Parts)''<br>• The coils will be made out of a pair of copper wire spools I purchased from Tech-Fixx through Ebay.com designed for use in electromagnets.<br>• These are known as magnet wires. |

| | + | |Let's Build the S.H.O. Drive! - Slide 056 of 176.png||'''Magnet Wires'''<br>''(Phase 3 Parts)''<br>• These are size 12 gauge on the American Wire Gauge scale. Each coil has approximately 100 feet (or 30 meters) of wire, and together they will form a ½” (or 13 mm) thick bundle of copper with a combined resistance of approximately 0.3 ohms, or less than 1/3rd of an ohm.<br>• These Essex Soderon 155 wires have a temperature rating of 311 degrees Fahrenheit or 155 degrees Centigrade. |

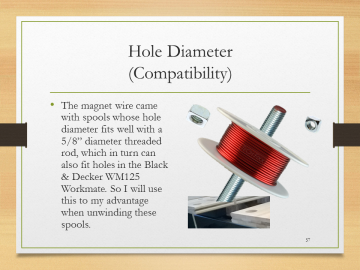

| | + | |Let's Build the S.H.O. Drive! - Slide 057 of 176.png||'''Hole Diameter'''<br>''(Compatibility)''<br>• The magnet wire came with spools whose hole diameter fits well with a 5/8” diameter threaded rod, which in turn can also fit holes in the Black & Decker WM125 Workmate. So I will use this to my advantage when unwinding these spools. |

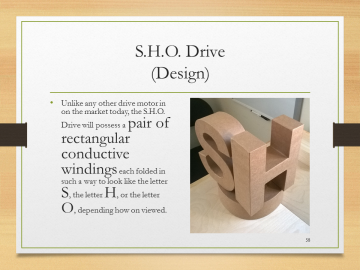

| | + | |Let's Build the S.H.O. Drive! - Slide 058 of 176.png||'''S.H.O. Drive'''<br>''(Design)''<br>• Unlike any other drive motor in on the market today, the S.H.O. Drive will possess a pair of rectangular conductive windings each folded in such a way to look like the letter S, the letter H, or the letter O, depending how on viewed. |

| | + | |Let's Build the S.H.O. Drive! - Slide 059 of 176.png||'''Custom Spool'''<br>''(Assembly)''<br>• Each copper spool will be wound into a rectangle winding with inside dimensions of 24” by 2¼” (or 610 mm by 57 mm).<br>• Then each winding will be carefully folded into the final form of the S.H.O. coil.<br>• Since a spool of these dimensions will be very hard to find on the market, if it exists at all, I will have to make it custom. |

| | + | |Let's Build the S.H.O. Drive! - Slide 060 of 176.png||'''Mailing Tube'''<br>''(Equipment)''<br>• The spool will be made out of a 25” (or about 635 mm) long section of a cardboard mailing tube. Pairs of notches ½” (or about 13 mm) deep will be cut into each end, and the wire will be wound through the resulting 24” by 2¼” (or about 610 mm by 57 mm) inner perimeter.<br>• The tube originally contained square acrylic tubes I ordered from Plastic-Craft (Phase 7). |

| | + | |Let's Build the S.H.O. Drive! - Slide 061 of 176.png||'''Nylon Fasteners'''<br>''(Phase 3 Tools)''<br>• To keep the copper winding bundle tight when curving it to the desired S-curve, several Hillman 3/8" Nylon Cable Clamps from Lowes will be fastened temporarily on the bundle using Hillman Nylon 10-24 Wingnuts and Screws also from Lowe’s. |

| | + | |Let's Build the S.H.O. Drive! - Slide 062 of 176.png||'''Curved Ruler'''<br>''(Tools)''<br>• I must ensure that the long side of the 24”x2¼” conductive winding has the correct form of S curve.<br>• So I will be using a 24”(or 610 mm) Flexible Curved Ruler by Staedtler that I purchased from inside an Artist & Craftsman Supply store. |

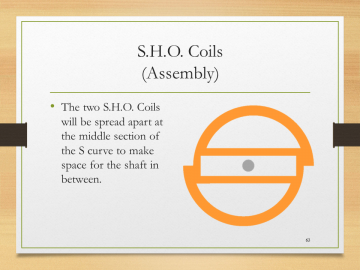

| | + | |Let's Build the S.H.O. Drive! - Slide 063 of 176.png||'''S.H.O. Coils'''<br>''(Assembly)''<br>• The two S.H.O. Coils will be spread apart at the middle section of the S curve to make space for the shaft in between. |

| | + | |Let's Build the S.H.O. Drive! - Slide 064 of 176.png||'''Curved Ruler'''<br>''(Tools)''<br>• The 12 American Wire Gauge copper wire is significantly rigid by itself, and it will be even more so when approximately 22 turns of such wire are bundled together in each S.H.O. coil<br>• Therefore I have used the 24” (or 610 mm) Flexible Curved Ruler by Staedtler, which is stiff in its own right, to trace various models for the S Curve of the S.H.O. Coils. |

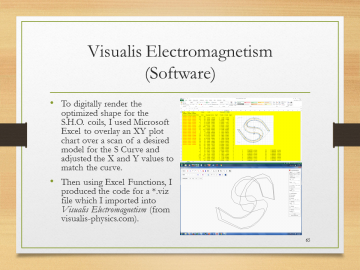

| | + | |Let's Build the S.H.O. Drive! - Slide 065 of 176.png||'''Visualis Electromagnetism'''<br>''(Software)''<br>• To digitally render the optimized shape for the S.H.O. coils, I used Microsoft Excel to overlay an XY plot chart over a scan of a desired model for the S Curve and adjusted the X and Y values to match the curve.<br>• Then using Excel Functions, I produced the code for a<br>•.viz file which I imported into Visualis Electromagnetism (from visualis-physics.com). |

| | + | |Let's Build the S.H.O. Drive! - Slide 066 of 176.png||'''Tubing Bender'''<br>''(Phase 3 Tools)''<br>• To form the S curves of the S.H.O. Coils, I will use a 1/4”-3/8” Tubing Bender by Pittsburgh from Harbor Freight Tools. |

| | + | |Let's Build the S.H.O. Drive! - Slide 067 of 176.png||'''Tubing Bender'''<br>''(Phase 3 Tools)''<br>• To hold the tubing bender to the workbench, I will use 3 in. Industrial C-Clamps that I obtained from a Harbor Freight Tools store. |

| | + | |Let's Build the S.H.O. Drive! - Slide 068 of 176.png||'''Ceiling Hooks'''<br>''(Phase 3 Parts)''<br>• To hold the winding into the desired configuration, I purchased 7/8” vinyl-coated ceiling hooks from Arrow Hardware through Amazon.com.<br>• These hooks are about the right size to hold each winding separately. They can also be turned as needed to conform to the S curves of the S.H.O. coils. |

| | + | |Let's Build the S.H.O. Drive! - Slide 069 of 176.png||'''Wood Panels'''<br>''(Disassembly)''<br>• Before I can drill pilot holes onto the wood panels for the ceiling hooks, I must unscrew the hinges from the wood panels, set aside the wood base blocks, and then pull out the panels off the bearings. |

| | + | |Let's Build the S.H.O. Drive! - Slide 070 of 176.png||'''Ceiling hooks'''<br>''(Assembly)''<br>• To drill pilot holes for the ceiling hooks, I will again use the 18 Volt Cordless 3/8 in. Drill by Drill Master that I purchased inside a Harbor Freight Tools store. |

| | + | |Let's Build the S.H.O. Drive! - Slide 071 of 176.png||'''Bundle Diameter'''<br>''(Compatibility)''<br>• Each of the two S.H.O. Coils should have a bundled cross-section of about 3/8” inch (or 10 mm) in diameter consisting of approximately 22 turns of 12 American Wire Gauge (or 2 mm diameter) wire.<br>• The openings in the ceiling hooks are 1/3” (or 8 mm) across. Therefore, the coils will be securely held into place by the hooks. |

| | + | |Let's Build the S.H.O. Drive! - Slide 072 of 176.png||'''Electrical Tape'''<br>''(Parts)''<br>• To provide an additional electrical barrier and thermal protection between the windings and the hooks, I will be using Scotch Professional Grade 35 Red Vinyl Electrical Tape that I purchased at Lowe’s. |

| | + | |Let's Build the S.H.O. Drive! - Slide 073 of 176.png||'''Drill Bits'''<br>''(Phase 3 Tools)''<br>• I have purchased a set of 7/64 in. Titanium Nitride High Speed Steel Drill Bits by Warrior from Harbor Freight Tools.<br>• These will allow to me drill pilot holes into the wood panels for the ceiling hooks. |

| | + | |Let's Build the S.H.O. Drive! - Slide 074 of 176.png||'''S.H.O. Coils'''<br>''(Assembly)''<br>• After I make the S.H.O coils and install the ceiling hooks, I will slide the wood panels back on the bearings, and then screw them back onto the base hinges.<br>• Then I will insert the S.H.O. Coils into the ceiling hooks. |

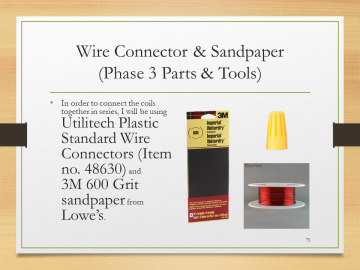

| | + | |Let's Build the S.H.O. Drive! - Slide 075 of 176.png||'''Wire Connector & Sandpaper'''<br>''(Phase 3 Parts & Tools)''<br>• In order to connect the coils together in series, I will be using Utilitech Plastic Standard Wire Connectors (Item no. 48630) and 3M 600 Grit sandpaper from Lowe’s. |

| | }} | | }} |

| | <div style="clear:both"></div> | | <div style="clear:both"></div> |