Difference between revisions of "Presentation"

From S.H.O.

| Line 32: | Line 32: | ||

|lines=10 | |lines=10 | ||

|footer= | |footer= | ||

| + | |Let's Build the S.H.O. Drive! - Slide 018 of 176.png||'''In Phase 1…<br>• First on the list is to create holes which will hold bearings for the S.H.O. Drive.<br>• Second is to install brass hinges which will connect the wood panels to the wood base.<br>• And third is to install square nuts onto the shaft. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 019 of 176.png||'''2 Barn Birdhouse Kits'''<br>''(Phase 1 Parts)''<br>• The wood panels I will be using will come from 2 SawDust Bros. Birdhouse Kits which I obtained from Woodcraft.<br>• Why birdhouse kits? Well each birdhouse kit is packed with many pieces of wood of various sizes, which I may use in the future. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 020 of 176.png||'''Saving Time'''<br>''(Protocols)''<br>• But the main reason why I purchased two Birdhouse kits was for the two front panels, which have holes that are nearly the right size for the project.<br>• I will use the front panels from each kit as support structures to carry the weight of the bearings, rotor, and conductive copper coils. | ||

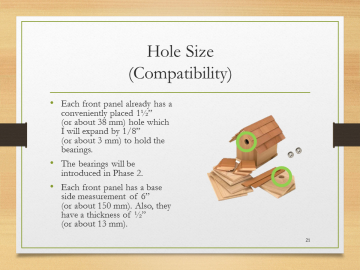

| + | |Let's Build the S.H.O. Drive! - Slide 021 of 176.png||'''Hole Size'''<br>''(Compatibility)''<br>• Each front panel already has a conveniently placed 1½”‘‘‘<br>''(or about 38 mm) hole which I will expand by 1/8”‘‘‘<br>''(or about 3 mm) to hold the bearings.<br>• The bearings will be introduced in Phase 2.<br>• Each front panel has a base side measurement of 6”‘‘‘<br>''(or about 150 mm). Also, they have a thickness of ½”‘‘‘<br>''(or about 13 mm). | ||

| + | |Let's Build the S.H.O. Drive! - Slide 022 of 176.png||'''Circle Template'''<br>''(Phase 1 Tools)''<br>• To mark the dimensions for the 1 5/8 ” (or about 41 mm) bearing holes, I bought a 42 circle template sheet by Timely from a specialty store called Artist & Craftsman Supply. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 023 of 176.png||'''Power Drill'''<br>''(Phase 1 Tools)''<br>• To expand the holes for the bearings, I purchased an inexpensive rotary tool from Ferm via Amazon.com. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 024 of 176.png||'''Portable Work Bench'''<br>''(Equipment)''<br>• I purchased from Black & Decker the WM125 Workmate through Amazon.com, which is foldable and has an adjustable width.<br>• The clamping wood pieces have a groove which, fortuitously, can hold the depth guide of the power drill. So this work bench will effectively function as an inexpensive “router table”. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 025 of 176.png||'''Dremel Accessory Set'''<br>''(Phase 1 Tools)''<br>• In order to finish the holes nicely to size, I will attach items from the Dremel 687-01 General Purpose Accessory Set I purchased at Fry’s Electronics. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 026 of 176.png||'''Sanding Bands & Drum'''<br>''(Phase 1 Tools)''<br>• The Dremel tools from the kit that I will use are the 432 Sanding Bands and the 407 Sanding Drum.<br>• The sanding area will be ½” (or about 13 mm) thick, which will be perfect for sanding into the ½” (or about 13 mm) thick wood panels which will hold the bearings. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 027 of 176.png||'''Plywood Surface'''<br>''(Equipment)''<br>• To make better use of the workbench for the rest of the project, I will cover the top with two pieces of Baltic Birch plywood from Woodcraft:<br>• The side lengths are 12” (or about 30 cm)''<br>• The thickness of each is 1/2” (or about 13 mm) | ||

| + | |Let's Build the S.H.O. Drive! - Slide 028 of 176.png||'''C-Clamps'''<br>''(Equipment)''<br>• To hold the plywood to the workbench, I will use 3 in. Industrial C-Clamps that I obtained from a Harbor Freight Tools store. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 029 of 176.png||'''Ash Wood Blocks'''<br>''(Phase 1 Parts)''<br>• I also have two separate Ash wood blocks, also from Woodcraft that are about 2 inches by 2 inches thick. That’s about 50 millimeters on each side. Their length is about 8 inches long, or about 200 millimeters. These blocks will serve as the “feet” of the S.H.O. Drive.<br>• If you’re wondering what Ash wood is used for, it’s a wood often used in baseball bats. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 030 of 176.png||'''Brass Hinges'''<br>''(Phase 1 Parts)''<br>• So how should I attach these panels to the base blocks? Well I could simply glue and nail these panels to the base like a normal person. But here I will do something different. <br>• From Woodcraft, I purchased these brass hinges, which I will use to attach the panels onto the ash wood blocks. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 031 of 176.png||'''Transparency'''<br>''(Protocols)''<br>• I am a bit extra-concerned about the craftsmanship of this effort, and it would obviously be simpler to glue and nail the pieces together. But I place more value in reducing the possible ways that are available to “trick” this device. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 032 of 176.png||'''Transparency'''<br>''(Protocols)''<br>• Furthermore, the device, when completed will be left uncovered and exposed to the surrounding elements and operated in multiple environments to reduce the number ways to trick this device. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 033 of 176.png||'''Transparency'''<br>''(Protocols)''<br>• I do want this device to be well-built enough to operate even when transporting it, to better distinguish it from rather immobile devices which, who knows, could be powered by an object hiding behind a wall or some other structure in the room. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 034 of 176.png||'''Metal Spring Clamps'''<br>''(Equipment)''<br>• Before drilling the pilot holes for the brass screws, I will clamp the Ash wood base blocks with Bessey XM7 3-Inch Metal Spring Clamps that I purchased from Woodcraft. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 035 of 176.png||'''Power Drill'''<br>''(Recap)''<br>• Earlier in this construction Phase, I will have used a rotary tool from Ferm and the Dremel 407 Sanding Drum to make neat circular holes for the bearings. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 036 of 176.png||'''Compact Power Drill'''<br>''(Tools)''<br>• However, to drill pilot holes for the brass screws, I will use an 18 Volt Cordless 3/8 in. Drill by Drill Master from Harbor Freight Tools. 3/8 in. is about 9.5 millimeters. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 037 of 176.png||'''Drill Bits'''<br>''(Tools)''<br>• I also purchased a set of 3/32 in. Titanium Nitride High Speed Steel Drill Bits by Warrior from Harbor Freight Tools.<br>• These will allow to me drill pilot holes into the Ash wood base blocks for the screws. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 038 of 176.png||'''Brass Screws'''<br>''(Parts)''<br>• After drilling the pilot holes, I will screw the hinges tight with HighPoint Solid Brass Screws that I purchased from Woodcraft.<br>• These are size #6 so they have a diameter of 5/16 in. (or about 8 mm) measured at the shank. The shank is the straight section next to the head of each screw. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 039 of 176.png||'''Screw Driver Set'''<br>''(Tools)''<br>• To tighten the screws through the brass brackets which connect the wood panels to the wood base, I purchased an iWork 53 piece Tool Set by Olympia Tools from Fry’s Electronics. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 040 of 176.png||'''Square Nuts and Rod'''<br>''(Phase 1 Parts)''<br>• And finally, the simplest task in Phase 1 is to install these threaded square nuts onto a threaded steel rod. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 041 of 176.png||'''Square Nuts and Rod'''<br>''(Phase 1 Parts)''<br>• These are zinc plated and have a fitting diameter of 5/8” (or about 16 mm) and have 11 threads per inch (11 TPI). I obtained these from Tacoma Screw.<br>• Their diameter matches the size for the bore hole of the fan, which I will describe in further detail in Phase 4. | ||

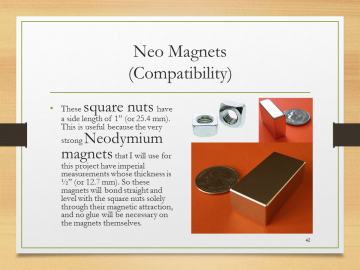

| + | |Let's Build the S.H.O. Drive! - Slide 042 of 176.png||'''Neo Magnets'''<br>''(Compatibility)''<br>• These square nuts have a side length of 1” (or 25.4 mm). This is useful because the very strong Neodymium magnets that I will use for this project have imperial measurements whose thickness is ½” (or 12.7 mm). So these magnets will bond straight and level with the square nuts solely through their magnetic attraction, and no glue will be necessary on the magnets themselves. | ||

| + | |Let's Build the S.H.O. Drive! - Slide 043 of 176.png||'''Bonding the Square Nuts'''<br>''(Assembly)''<br>• I will secure the position of the square nuts onto the shaft with a special-purpose glue called Loctite Threadlocker Red 271, which I purchased at Lowe’s.<br>• This is necessary so that the torque applied to magnet will transfer to the shaft. | ||

}} | }} | ||

<div style="clear:both"></div> | <div style="clear:both"></div> | ||

==Phase 2== | ==Phase 2== | ||

| + | {{Gallery | ||

| + | |width=360 | ||

| + | |align=center | ||

| + | |lines=10 | ||

| + | |footer= | ||

| + | }} | ||

| + | <div style="clear:both"></div> | ||

| + | ==Phase 3== | ||

| + | {{Gallery | ||

| + | |width=360 | ||

| + | |align=center | ||

| + | |lines=10 | ||

| + | |footer= | ||

| + | }} | ||

| + | <div style="clear:both"></div> | ||

| + | ==Phase 4== | ||

| + | {{Gallery | ||

| + | |width=360 | ||

| + | |align=center | ||

| + | |lines=10 | ||

| + | |footer= | ||

| + | }} | ||

| + | <div style="clear:both"></div> | ||

| + | ==Phase 5== | ||

| + | {{Gallery | ||

| + | |width=360 | ||

| + | |align=center | ||

| + | |lines=10 | ||

| + | |footer= | ||

| + | }} | ||

| + | <div style="clear:both"></div> | ||

| + | ==Phase 6== | ||

| + | {{Gallery | ||

| + | |width=360 | ||

| + | |align=center | ||

| + | |lines=10 | ||

| + | |footer= | ||

| + | }} | ||

| + | <div style="clear:both"></div> | ||

| + | ==Phase 7== | ||

| + | {{Gallery | ||

| + | |width=360 | ||

| + | |align=center | ||

| + | |lines=10 | ||

| + | |footer= | ||

| + | }} | ||

| + | <div style="clear:both"></div> | ||

</center> | </center> | ||

Revision as of 21:01, 20 April 2016

Contents

[hide]Introduction

|

Phase 1

|